|

|||||

|

|

|

|||

|

|||||

|

|

||||

|

|||||

|

|||||

|

|||||

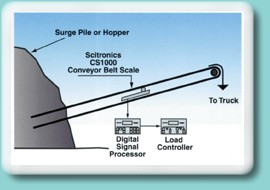

The SciTronics Load Controller is designed to operate in conjunction with a SciTronics Conveyor Belt Scale or Weighbelt Feeder. A 4-line by 20-character alphanumeric display provides direct reading of the truck I.D., set point (load size), load (tons loaded), and ready-conveyor-feeder conditions.

Typical Load Controller applications include truck and rail loading, as well as batching one or more ingredients into a bulk material process.

The Load Controller stores up to 15 different truck I.D. numbers with 15 different load sizes. It is capable of controlling multiple feeder gates and interfacing with virtually all tape or ticket readout printers.

In addition to having start-stop control of the conveyor system, the Load Controller is "user friendly" when interfaced with a printer and alarm. Optional accessories include remote control stations and vandal-proof enclosures.

- • Microprocessor

based "user friendly"

• Capable of storing up to 15 different

ID numbers with 15 different load sizes

- • Controls multiple

gates

• Easy to program

• Easy-to-read display

• Three 1/2" electrical entries

• Standard 3-year warranty

• Compatible with many printers and

large digital readouts

legal hauling weight) then presses the "START" key on the key pad.

2. The conveyor starts and then a few seconds later the prefeeder starts.

3. Material passing over the belt scale causes a "weight signal" to

be transmitted to the load controller.

4. The microprocessor in the load controller continuously compares

the actual weight to the set point (tons selected).

5. Upon reaching the set point, the prefeeder stops, and after a

predetermined time the conveyor stops.

6. The truck drives away and the load controller resets.